Transform the laborious task of bin picking into an automatic and standardized process, freeing up your staff for more specialized challenges.

Bin Picking of injection bulk material

Automatically separate transparent injection bulk material

Automatically separate transparent injection bulk material

Transform the laborious task of bin picking into an automatic and standardized process, freeing up your staff for more specialized challenges.

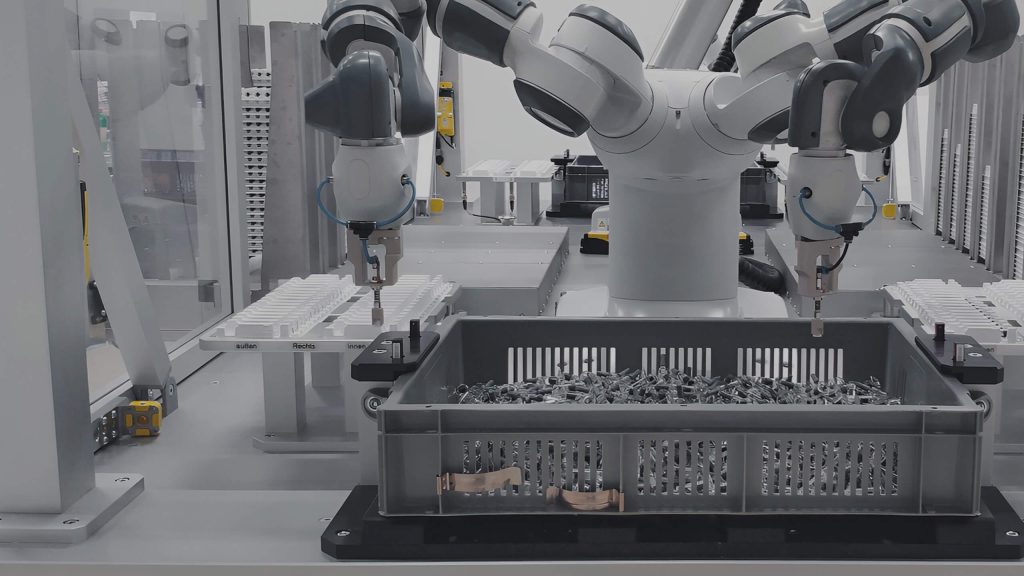

Bin picking involves detecting individual, loose components, such as transparent syringe barrels, and picking them up from a tray or a bin in order to efficiently arrange them for storage, transport or subsequent manufacturing steps.

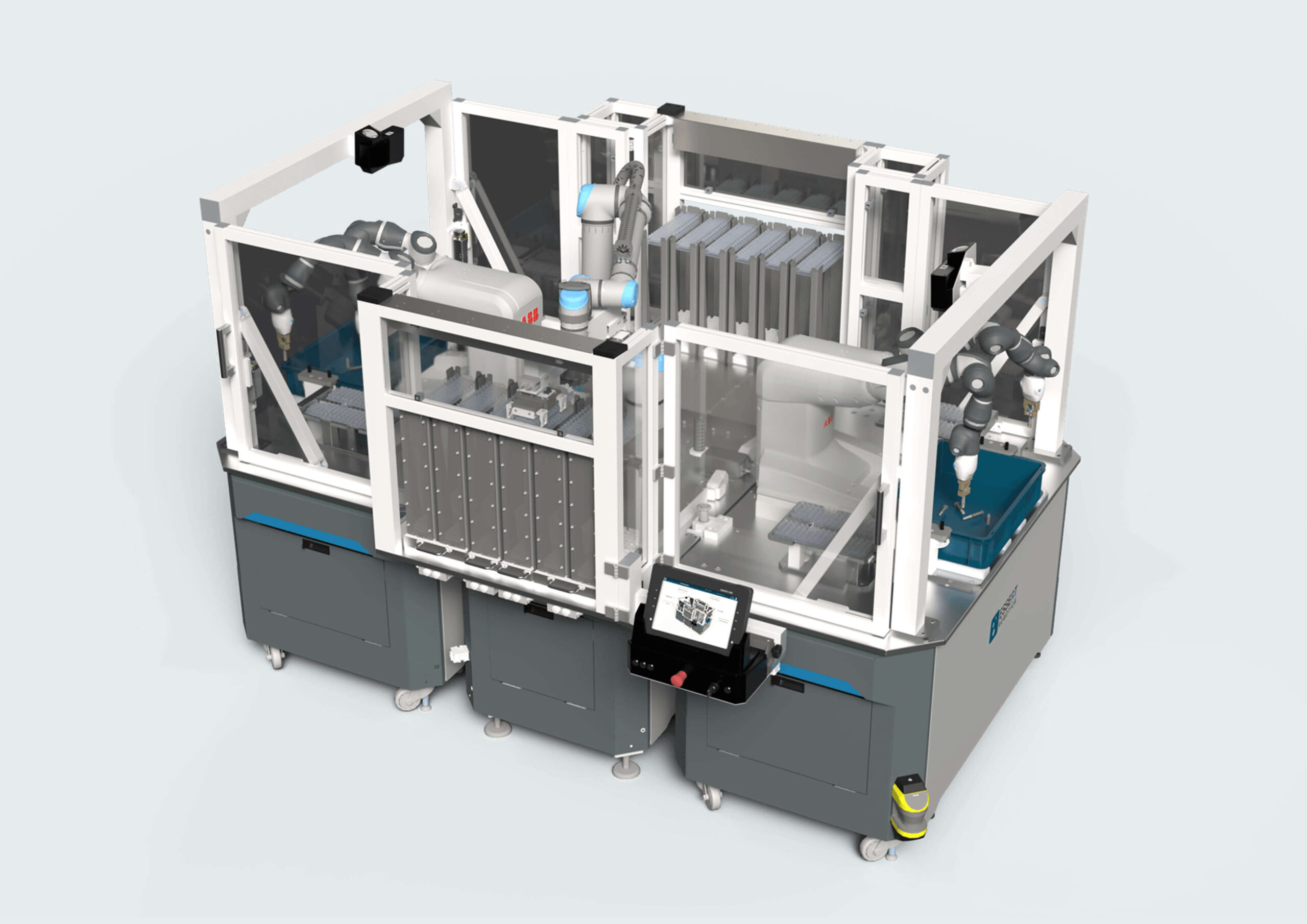

Customized as a robotic bin picking system, ESSERT’s solution simplifies and automates the laborious separating, sorting and arranging process.

Supported by Artificial Intelligence and 3D sensor technology, the Bin Picking Solution can process even sensitive medical products and their respective components.

Clients

In High Mix / Low Volume (HMLV) manufacturing environments, automated bin picking solutions have emerged as a game-changer. These systems, equipped with advanced technologies like 3D vision and tactile sensors, are well-suited for the challenges of HMLV settings.

They excel at random bin picking, efficiently handling loose components of different sorts. The robotics applications are vast, from late-stage customized products and personalized medicine production to optimizing laboratory workflows.

Automated bin picking solutions offer an array of benefits that transform manufacturing processes.

By seamlessly integrating advanced technologies like 3D vision and robotics, these systems enhance efficiency, reduce errors, and maximize productivity.

The automated separation of bulk material simplifies the sorting and gripping of products. A robot arm with a specialized gripper optimizes this process.

Employees are relieved of repetitive tasks, allowing them to concentrate on more complex and value-adding activities. This change increases productivity, especially in view of staff fluctuations and demographic changes. At the same time, consistent and error-free handling of components is guaranteed.

Automated bin picking significantly reduces the risk of human errors and contamination, concurrently enhancing staff safety by minimizing exposure to hazardous substances.

Advanced grippers and robotic precision ensure components are consistently handled, mitigating contamination risks. Minimizing human involvement in these processes can reduce the potential for errors, contributing to a safer and more reliable manufacturing environment. This holds particular importance in industries with stringent quality and hygiene standards.

Automated bin picking improves transparency and traceability in production. Automated documentation and real-time monitoring ensure that every step is accurately recorded.

Real-time tracking enables quick localization of anomalies and improves overall quality control. The data provides insights into process efficiency and promotes continuous improvement.

The compact, modular architecture of our standardized modules optimizes the use of your available production space.

This space-saving approach is particularly valuable in industries where space limitations are a challenge. It helps to reduce operating costs and improve efficiency.

Late-stage customization entails adapting products to meet specific customer or market requirements just before they are delivered. This process demands precision and flexibility.

Automated bin picking, facilitated by industrial robots, is vital in this context. It ensures accurate and efficient handling of components, allowing for quick product adjustments. By reducing errors and minimizing setup times, automated bin picking enhances the productivity and agility required for late-stage customized product manufacturing.

The bin-picking solution from ESSERT Robotics enables automated, robot-controlled picking of pre-filled syringes. Thanks to high-resolution vision and sensor technology, it can handle even extremely sensitive components - even in different lighting conditions.

One of its special features is its flexibility and modularity. The system can be adapted to changing work processes, different configurations and components.

The operating system, ESSERT OS, gives you full control. An intuitive user interface allows you to easily make process changes without the need for programming skills.

Our solution was recently awarded the prestigious ISPE RAYA Award. In collaboration with Vetter Pharma, we won the "Fill & Finish" category with our "Speed Bin Picking" project.

Contact

We would be happy to discuss with you how our robotic platform can help to achieve your goals.