We help you future-proof your medical device assembly by increasing production quality and saving valuable time.

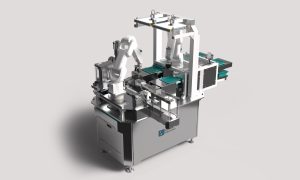

Assembly of autoinjectors, syringes, and PENs

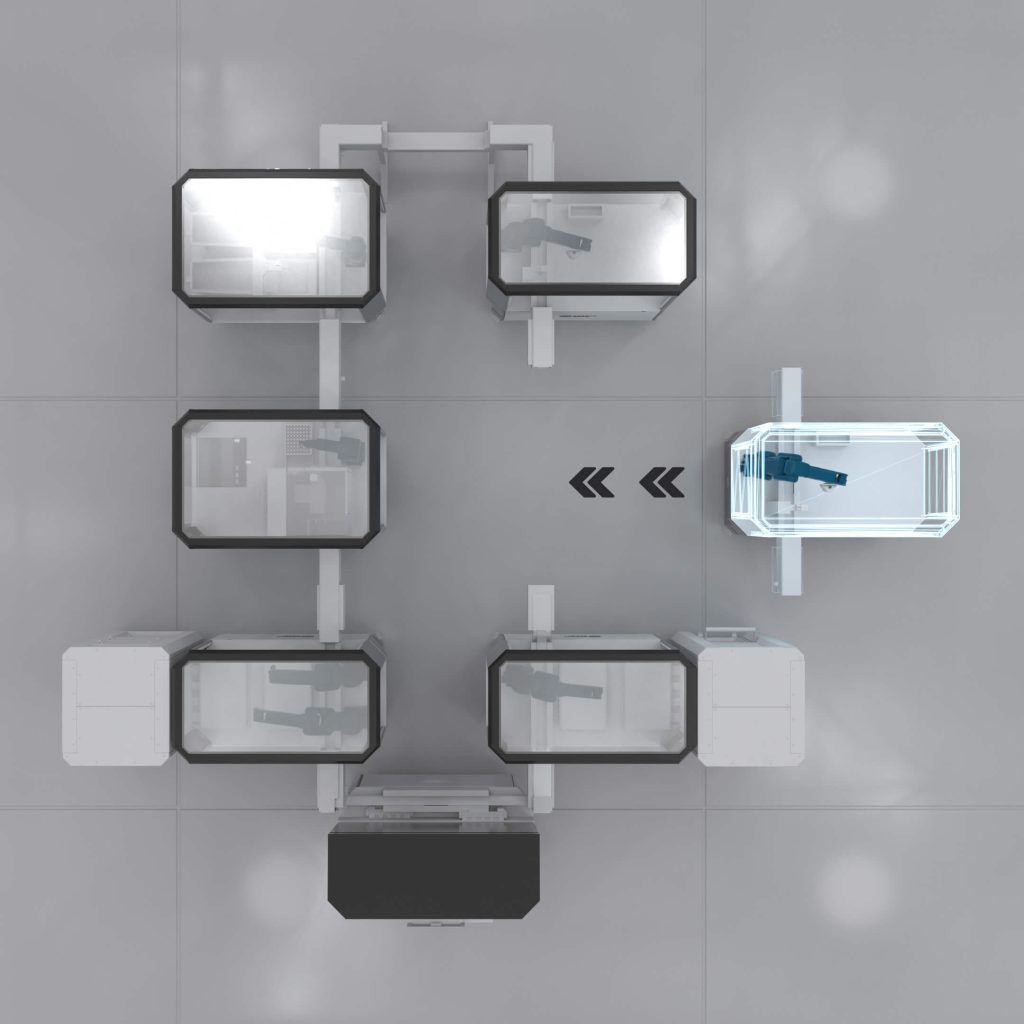

We provide a flexible Assembly solution for variable batch sizes and high format variance. As a specialist in cutting-edge robotic life science automation, we offer modular, flexible and scalable robotic solutions for your High Mix / Low Volume (HMLV) requirements with minimal setup time – successfully applied in the assembly of secondary packaging or medical devices as well as in clinical studies.

Medical Device Assembly.

The trend toward product customization and decentralized production increases the need for flexibility.

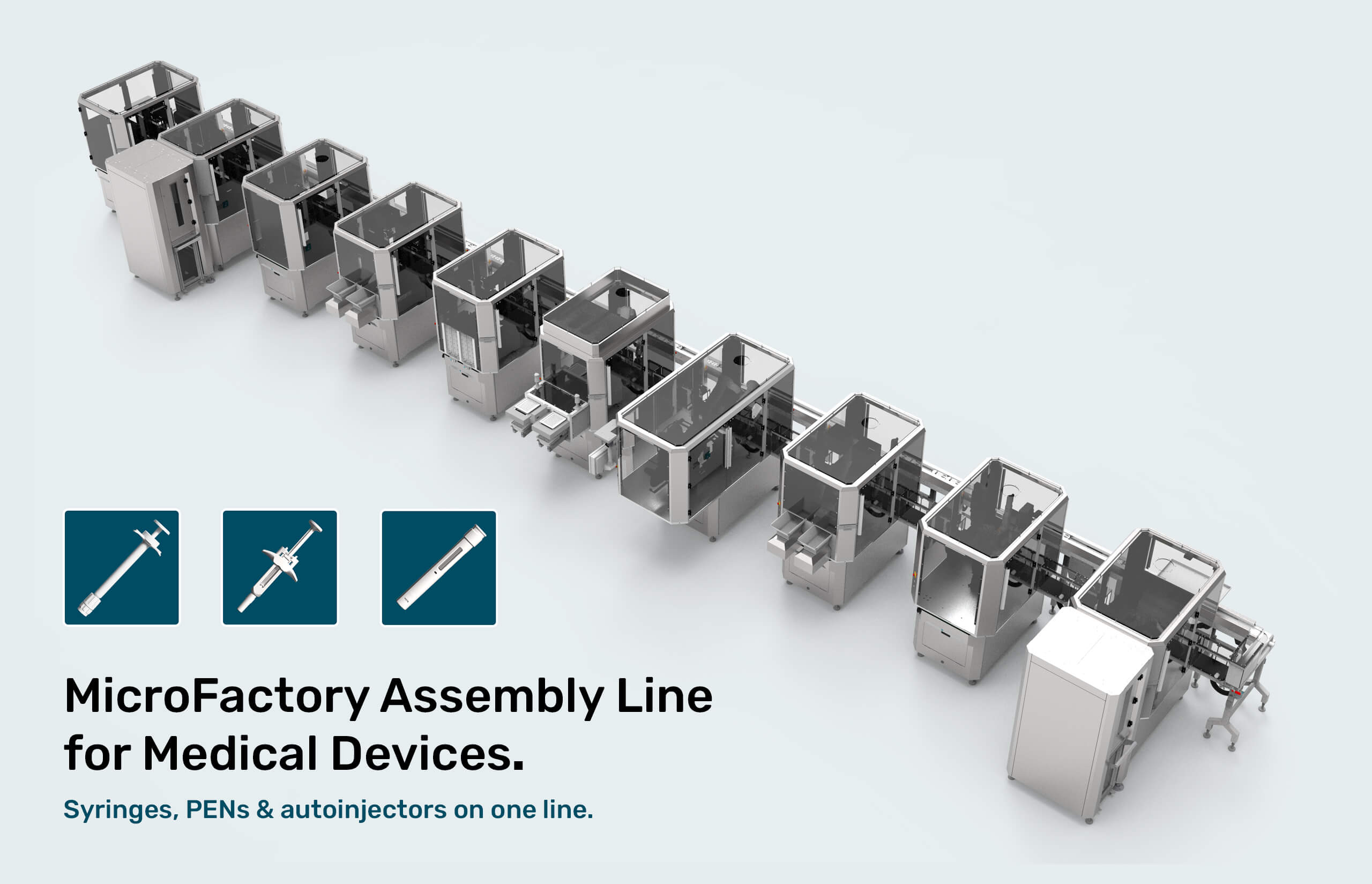

The 'MicroFactory Assembly Line' is the perfect fit for your device assembly.

Autoinjectors, Syringes, and PENs on one line with fast, automated changeover to new products and minimized manual labor.

Big Players like 'ROCHE' rely on our MicroFactory Assembly Line for Medical Devices.

“At Roche, we were looking for a modular, flexible solution for assembling different devices and found this solution in ESSERTs automation platform. The collaboration with ESSERT was characterized by a high level of innovation.”

Philip Schneider

Drug Product Manufacturing Network Technology Lead

Have a quick look into the MicroFactory

Assembly Line.

Discover some of our single

process modules.

We help you to automate your medical device assembly - worldwide.

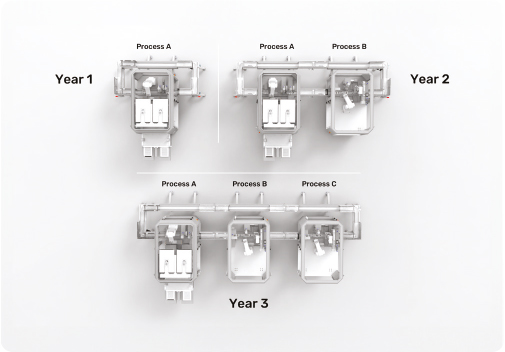

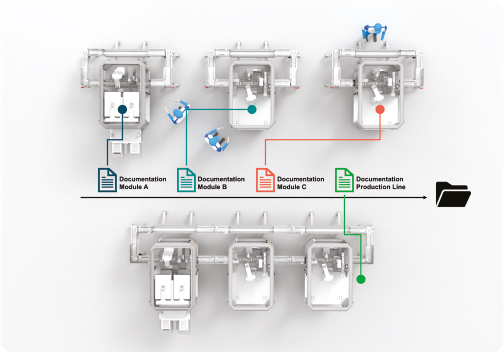

Single process to full automation.

With the ESSERT MicroFactory, you can align individual manufacturing steps to a fully automated production process.

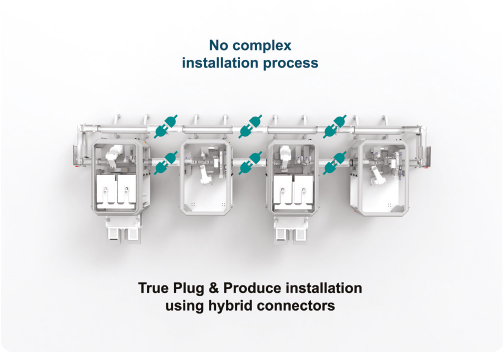

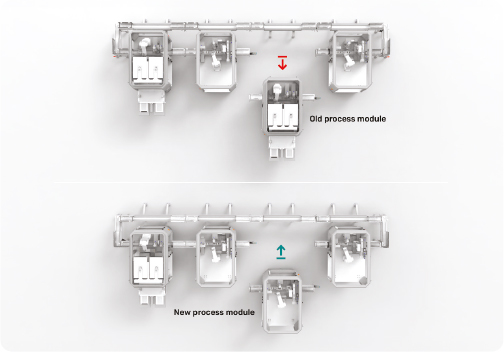

- Standardization: Our standardized robot modules provide the perfect basis for your processes.

- Process Modules: Perfectly designed, standardized process modules to meet any application.

- ESSERT MicroFactory: Probably the most intelligent and flexible interaction of processes to form a scalable manufacturing line.

Pre-series validation.

Use our standardized process modules to automate your manual processes.

You can validate the automated processes in the pre-series and later transfer them to a MicroFactory with little effort, thus scaling your production.

Key Features of the MicroFactory

automation platform.

Blog

What's new?

Contact

Contact our team

We would be happy to discuss with you how our robotic platform can help to achieve your goals.