Robotics in

Pharma

Advanced solutions for Assembly & Packaging, Fill & Finish Handling, Clinical Trials and Lab Scale.

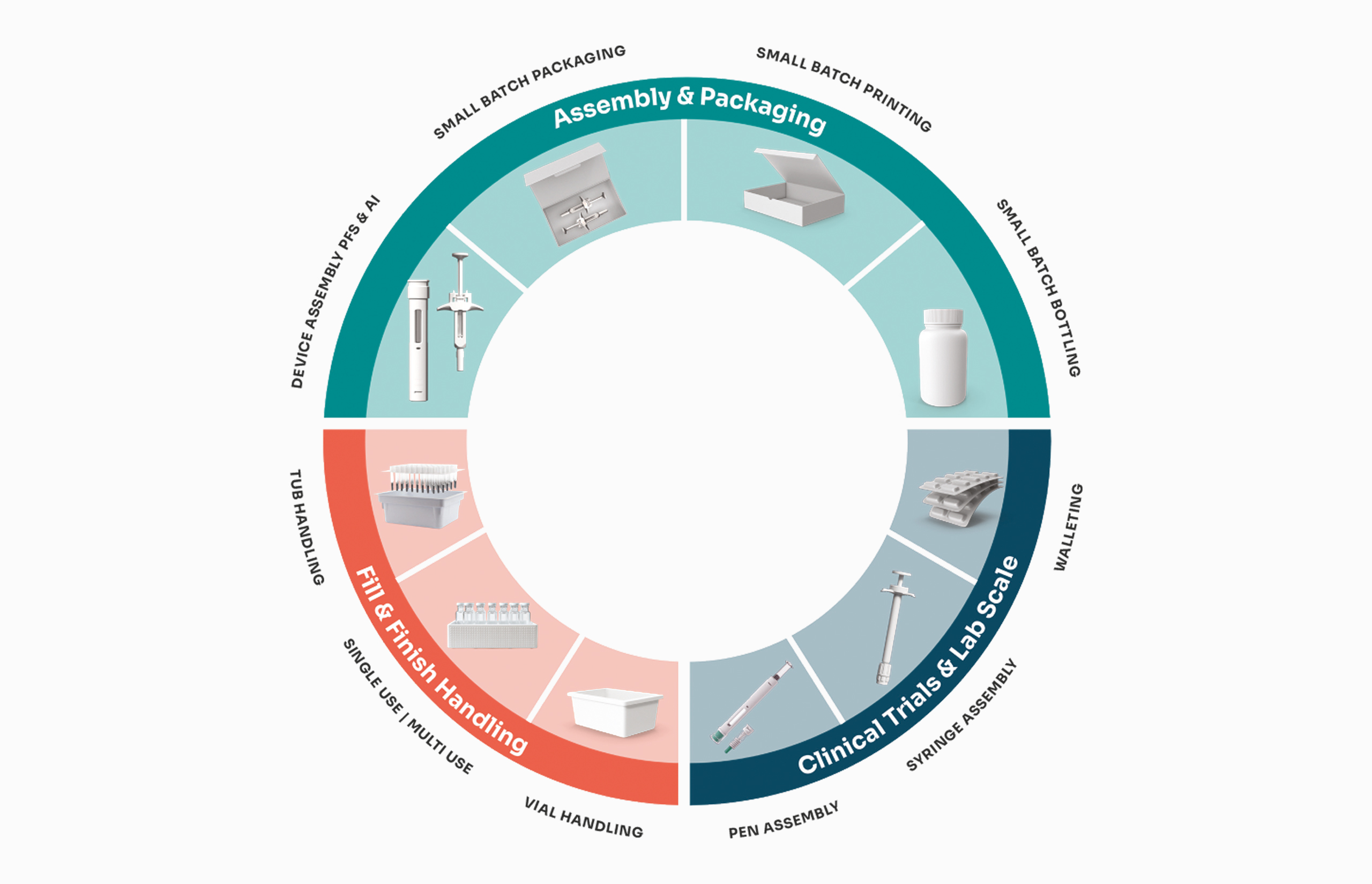

Our Pharma portfolio

We offer innovative solutions for the automation of your pharmaceutical processes, such as device assembling, small batch production, tub and vial handling or other tasks individually defined by yourself.

Our standardized automation platform provides the right solution for each of your automation goals.

Discover a selection of our projects.

Browse through some of the work we’ve done for our customers.

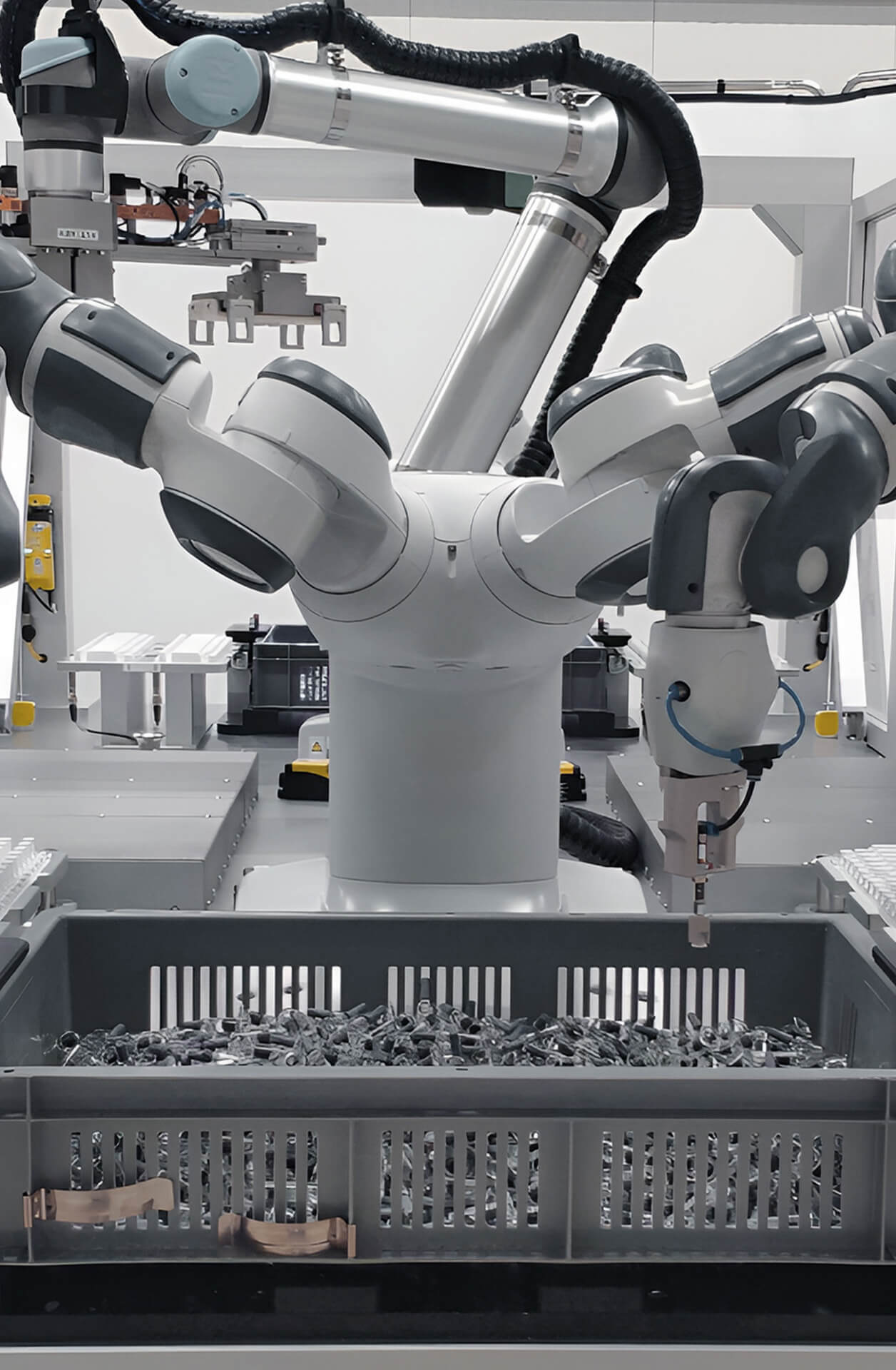

Production line for autoinjectors, syringes, and pens.

Semi-automatic device assembly of micro batches and clinical studies.

Loading and unloading for Filling, Inspection, and Secondary Packaging machines.

Fully automated modular Packaging solution for parenteral injection devices.

Fully automated picking solution for medical devices.

Clients

Real businesses,

real results.

At Roche, we were looking for a modular, flexible solution for assembling different devices and found this solution in ESSERT´s automation platform. The collaboration with ESSERT was characterized by a high level of innovation and the willingness to adapt to the requirements of the pharmaceutical industry.

The robot workstation impresses with its flexibility, scalability and integration of state-of-the-art camera technologies.

Pharmaceutical automation refers to the utilization of advanced technologies and automated systems within the pharmaceutical industry to streamline and optimize processes.

The biopharma industry has been slow to adopt digital technologies like AI, despite demographic shifts pushing for more automation. Decentralized production and personalized medicine further emphasize the need for such solutions. ESSERT Robotics stands out, offering specialized automation for these...

Automation in pharmaceutical manufacturing boosts efficiency through improved precision, speed, and data management, while ensuring compliance and reducing costs. Systems minimize human errors and enhance product quality. Though integration can be challenging, companies like ESSERT Robotics offer adaptable solutions that...

Process automation is the use of technology to optimize and streamline processes, reducing manual effort and enhancing efficiency. ESSERT Robotics provides process automation solutions, particularly in the pharmaceutical industry.

In this article, we will take a closer look at ten providers for respective solutions required by pharmaceutical companies and the life sciences industry.