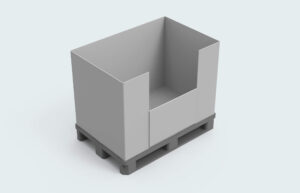

Automate repetitive tasks and relieve your employees with a fully automated and collaborative robot workstation for your Tub loading/unloading tasks.

You are missing out on automation potential.

You already have an automated filling, inspection or packaging system. Maybe you are in the process of purchasing additional machines for your secondary processes? But one thing is usually certain: the loading or unloading of your tubs is done manually by a real person.

Meet the award winning 'RoboTub'.

A fully automated, vision based, flexible robotic solution for your Tub loading and unloading tasks.

Based on our true modular MicroFactory automation platform.

Tailored to your needs, available in multiple configurations.

World-class CDMOs like 'VETTER Pharma' rely on RoboTub.

“Due to the high level of automation, one single RoboTub module can reduce the number of operators down to 1. The system has already paid for itself after 1 year.”

Arno Schroff

Department manager for plant and site development.

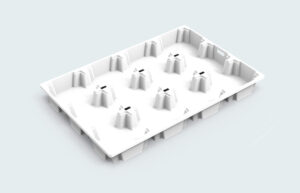

Supported Features and Add-ons

Take a look at some supported features and add-ons.

Something missing? Get in Touch!

Discover our different configuration models.

Tailored to your needs.

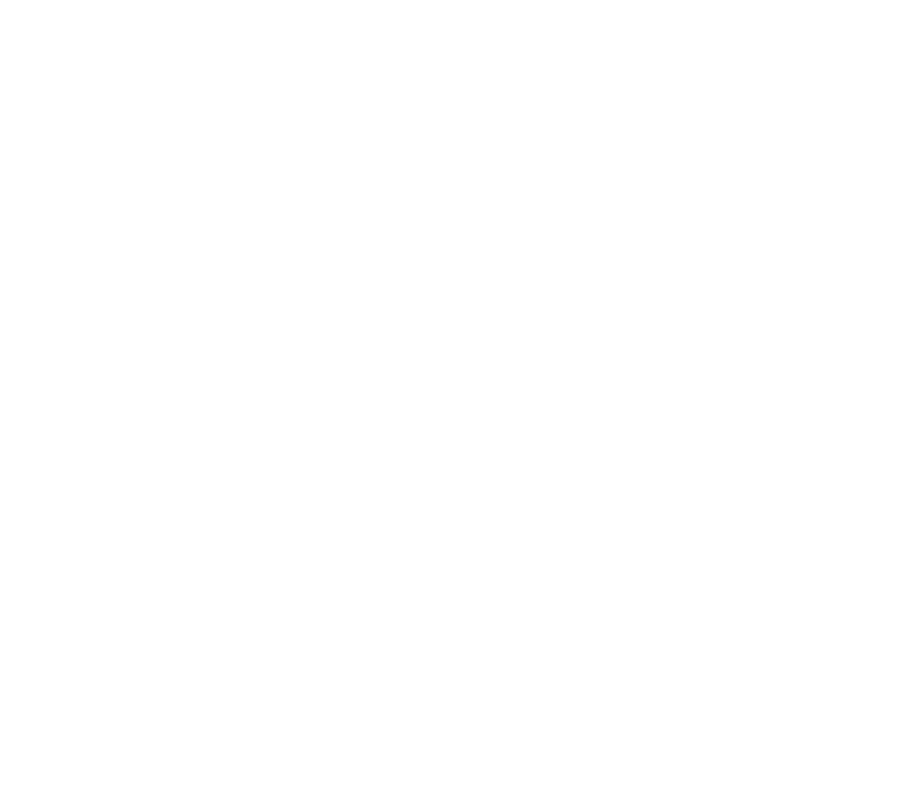

RoboTub 300

The RoboTub 300 basic configuration model for the loading and unloading of up to 3 Tubs per minute.

- 1 collaborative Robot

- 1 Material Handling Spot

- Expandable with a wide range of supported features and add-ons

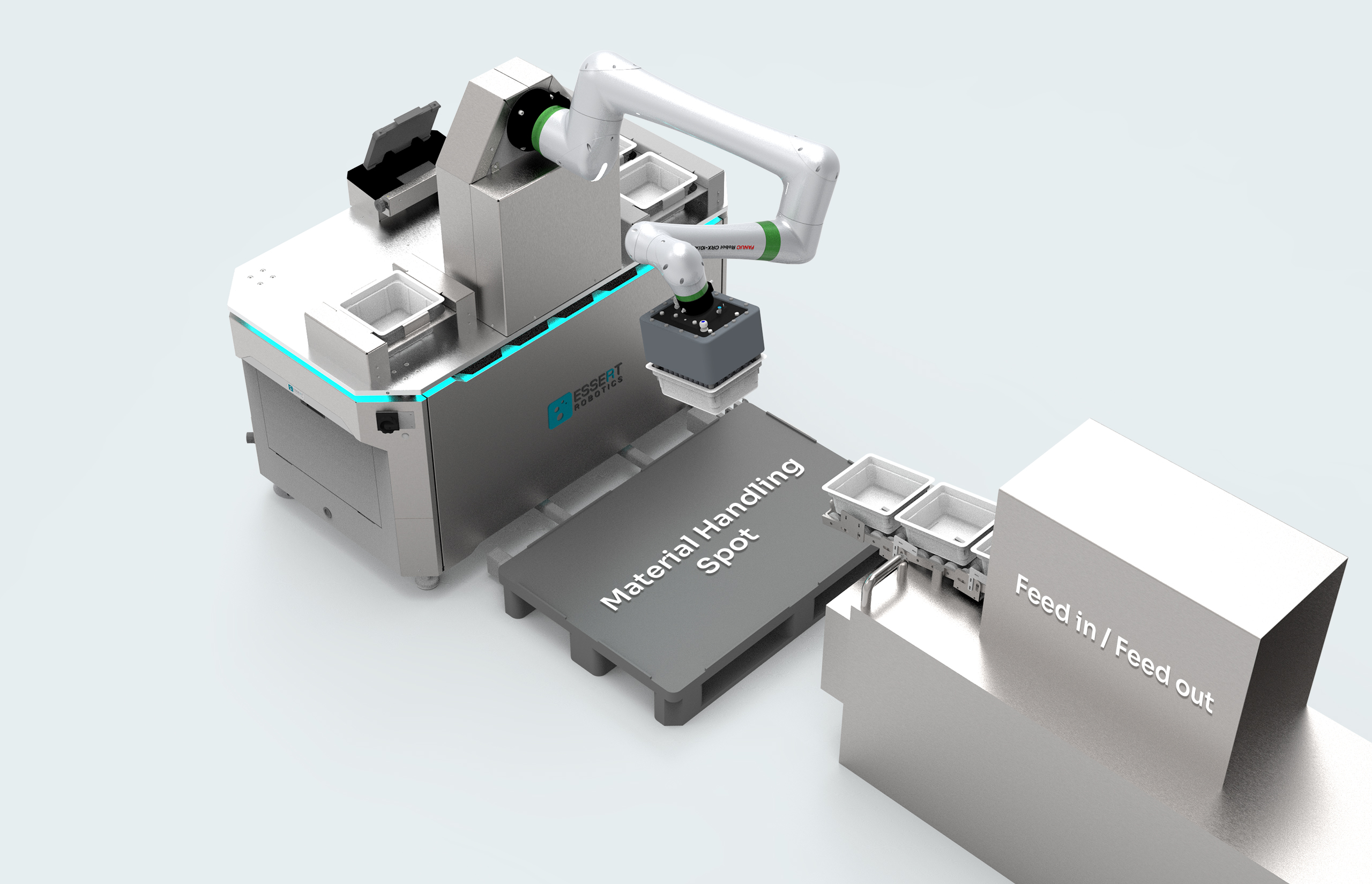

RoboTub 600

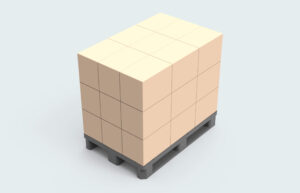

The RoboTub 600 configuration model for higher Output up to 6 Tubs per minute.

- 2 collaborative Robots

- 2 Material Handling Spots

- Uninterrupted pallet exchange

- Expandable with a wide range of supported features and add-ons

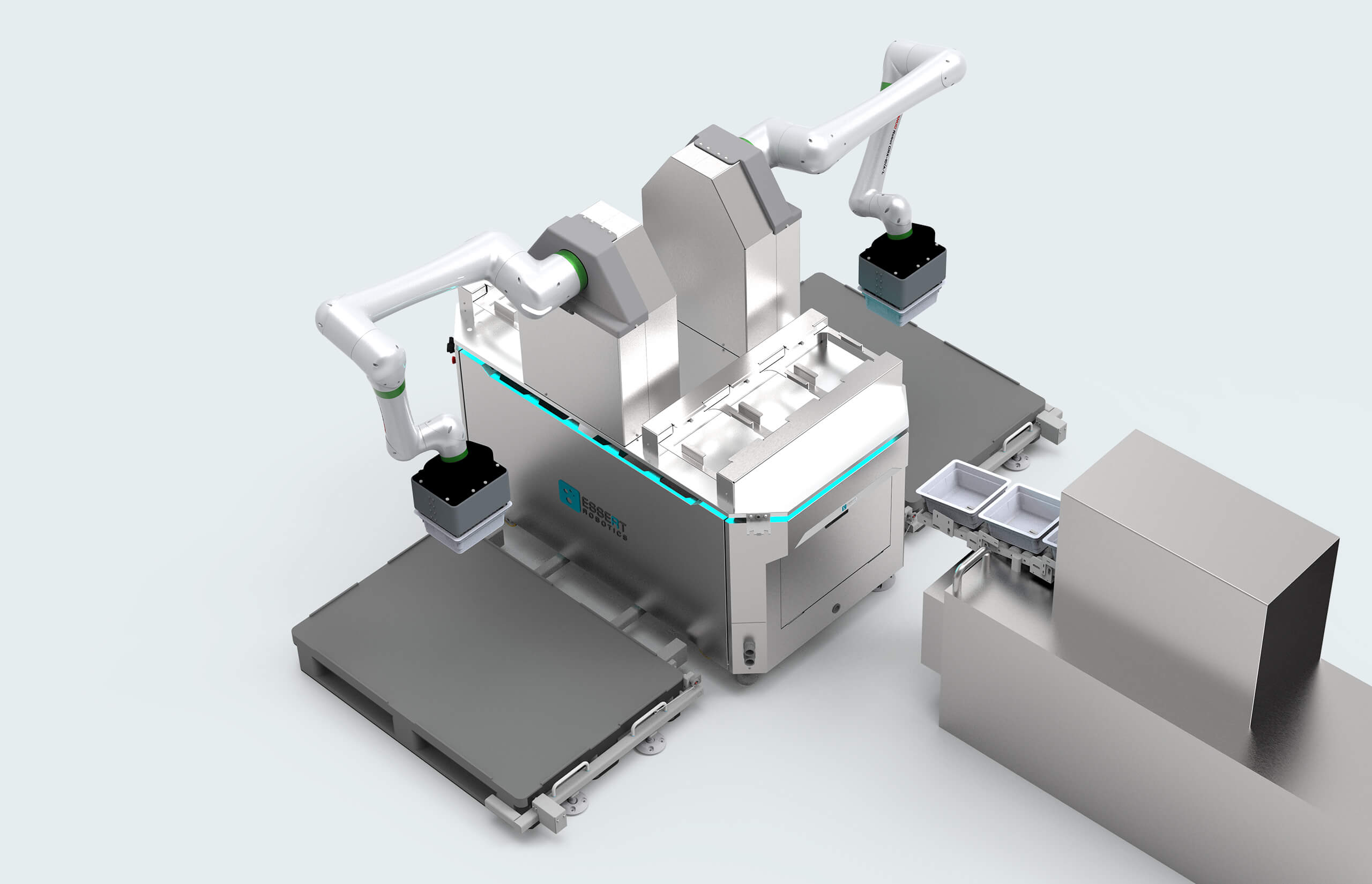

RoboTub 1000

The RoboTub 1000 configuration model for the loading and unloading of up to 10 Tubs per minute.

- 4 collaborative Robots

- 2 Material Handling Spots

- Uninterrupted pallet exchange

- Expandable with a wide range of supported features and add-ons

Benefit from true advantages.

Showcase of the RoboTub 300 model with

the Divider Layer Feeding Add-on.

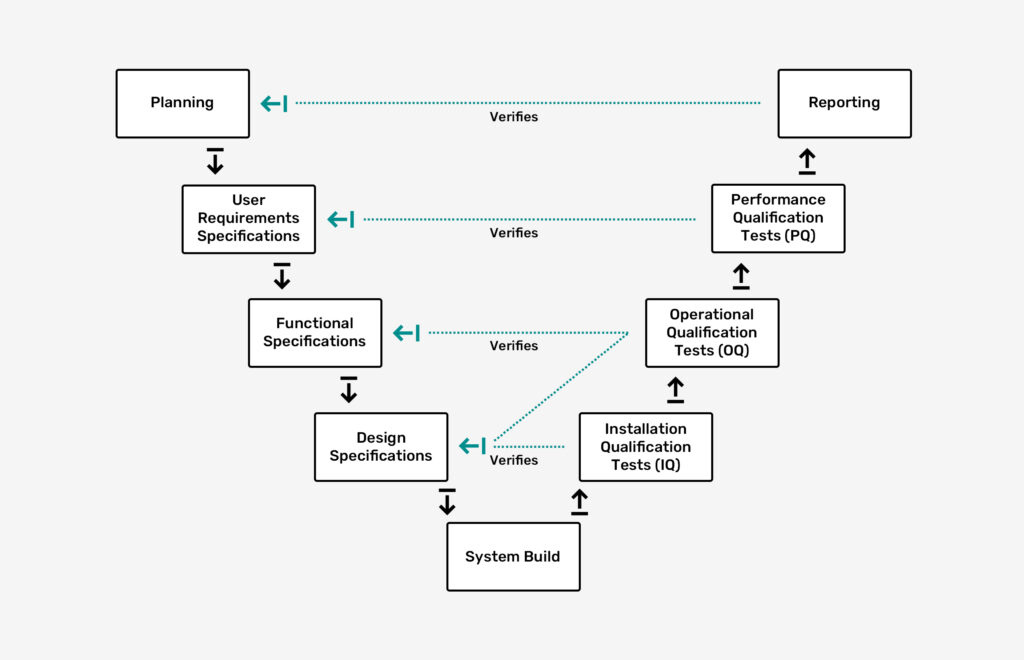

GMP and GAMP Services.

We adhere to GMP and GAMP guidelines and provide comprehensive documentation, validation, and qualification.

Our services include traceability matrix, risk analysis, Failure Modes and Effects Analysis (FMEA), design documentation, qualification, CE conformity assessment, audit trails, change control, training documentation, internal audits, Standard Operating Procedures (SOPs), deviation management, and data integrity to ensure full compliance and customer satisfaction.

Blog

What's new?

Contact

Contact our team

We would be happy to discuss with you how our robotic platform can help to achieve your goals.