What is an industrial robot?

Industrial robots are central to the evolution of modern manufacturing, playing a crucial role in enhancing efficiency, precision, and safety. They take over tasks that had previously been carried out by staff, relieving them from laborious, sometimes dangerous or unhealthy work.

In this article, we will discuss the concept of industrial robots in detail: We’ll uncover the technological innovations involved in this branch of robotics and explore the applications they are indispensable at.

What is meant by industrial robotics?

Industrial robotics encompasses the application of autonomous machines to perform tasks within a manufacturing environment, heralding a new era of automated efficiency. These specialized robots, designed for industrial settings, exhibit the ability to execute a range of complex operations with precision and speed.

The International Federation of Robotics refers to the definition of the International Organization of Standardization when it described the industrial robot as “automatically controlled, reprogrammable multipurpose manipulator, programmable in three or more axes, which can be either fixed in place or fixed to a mobile platform for use in automation applications in an industrial environment”.

Unlike other types of robotics, such as those used in service or domestic sectors, industrial robots are designed to handle rigorous, repetitive tasks in a structured setting, often involving heavy-duty machinery and precision-controlled processes.1 2

Industrial robot – how does it work?

The operation of an industrial robot involves a precise interplay of mechanics, electronics, and cutting-edge software. In general, industrial robots follow programmed instructions to execute tasks with a level of accuracy and speed often unmatched by human counterparts.

The process begins with sensory inputs from various detectors, such as cameras and sensors, providing real-time data about the robot’s environment. This information is then processed by the robot’s control system, which interprets the data and generates corresponding commands for the robotic arms and tools. The robot’s actuators, powered by electric, hydraulic, or pneumatic systems, then translate these commands into precise movements, allowing the robot to perform tasks with the required dexterity.

Typical components of industrial robots

As already stated, industrial robots consist of a variety of different components – some typical ones include:

Robotic arms

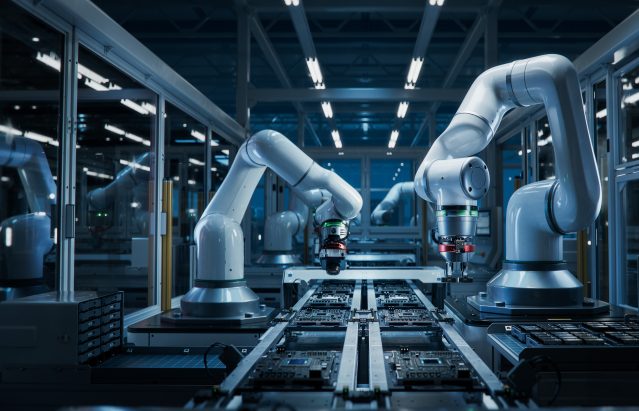

The robotic arms serve as the fundamental limbs of the robot, boasting multiple joints that provide flexibility. They enable a wide range of movements and orientations, allowing the robot to navigate and manipulate its surroundings.

End effectors

Positioned at the end of robotic arms, end effectors are specialized tools or attachments designed to carry out specific tasks. Examples include grippers for material handling, welders for joining processes, or sensors tailored to the robot’s application, enhancing its versatility.

Sensors

Industrial robots are equipped with an array of sensors that provide real-time data about their surroundings. These sensors include cameras for vision systems, tactile sensors for touch feedback, and proximity sensors for navigation. This sensory input ensures adaptability to different environments and enhances the robot’s situational awareness.

Controllers

The controller serves as the brain of the robot, housing the control system responsible for interpreting and executing programmed instructions. This crucial component determines the sequence of movements, manages overall coordination, and ensures that the robot performs tasks with the necessary precision and accuracy.

Actuators

Actuators are devices responsible for translating control signals into physical movements. Industrial robots employ various types of actuators, including electric, hydraulic, or pneumatic systems. These actuators enable the robot to execute precise and dynamic actions, contributing to its versatility in different applications.

Power supply

Industrial robots are usually powered by electricity, with energy sources tailored to their specific requirements. A reliable power supply is essential for sustained and uninterrupted operation, and has to comply with the specific application of the robot – whether or not a robot is mobile, for instance, has to be taken into consideration.

Teaching pendant

The teaching pendant is a portable control device that allows operators to program, operate, and monitor the robot. This handheld interface facilitates manual guidance and programming adjustments, empowering operators to interact with the robot in a user-friendly manner.

Applications of industrial robots

Industrial robots find versatile applications across diverse sectors, revolutionizing manufacturing processes.

In automotive manufacturing, robots perform precision welding, assembly, and painting tasks. In electronics, meanwhile, they handle intricate assembly processes. Logistics, on the other hand, benefit from robots in material handling and packaging.

Industrial robots can assist in hazardous environments, such as nuclear facilities or disaster sites. And industries like food and pharmaceuticals utilize robots for sanitary and other delicate tasks.

Robots for the pharmaceutical industry – powered by ESSERT Robotics

In the pharmaceutical industry, robotics has become a linchpin for precision and efficiency. The demand for consistent quality, stringent compliance with regulations, and the need for error-free operations make industrial robotics indispensable – be it dispensing, medical device assembly, or packaging tasks.

In these fields, ESSERT Robotics emerges as a game-changer: Its ADVANCED Robotic Workstation is designed to meet the highest demands for functionality, scalability, and ease of use. With a range of robotic workstation modules, it caters to diverse applications, ensuring flexibility and precision in pharmaceutical manufacturing. Furthermore, changeover times can be held short, as software-based adaptations can be effected within minutes.

The ESSERT MicroFactory, on the other hand, is the basis for an entire, highly flexible production line in High Mix / Low Volume environments. Built on a modular architecture, it allows high adaptability by allowing the individual integration of different components. This innovative approach further redefines how pharmaceutical companies approach production, offering efficiency and customization without sacrificing scalability or quality.

Read more about robotics

Robots in manufacturing: revolutionizing production processes

Robotic manufacturing companies

Cobot – all you need to know about collaborative robots

Robotics in the pharmaceutical industry

Robotics: 7 facts you need to know

- Industrial Robots. Definition. 02.2024 IFR. https://ifr.org/industrial-robots ↩︎

- ISO 8373:2021(en). Robotics — Vocabulary. ISO, 02.2024. https://www.iso.org/obp/ui/#iso:std:iso:8373:ed-3:v1:en ↩︎