Robotics: 7 facts you need to know

The field of robotics is full of surprising facts. With a utopian idea at its origin that has since become reality in the form of automation in different forms, from industrial robots to service robots, humanoids and collaborative robots, the future of robotics has yet to reach its peak.

Here are seven stunning facts about robotics – let’s discover its origin, the different applications of robots, and the increasing success of robots in the pharmaceutical industry.

Definition of robotics

Robotics is a multidisciplinary field involving the design, construction, operation, and use of robots to perform tasks typically carried out by humans or in environments unsuitable for humans. It encompasses elements of mechanical engineering, electrical engineering, computer science, and artificial intelligence. (Brittanica, 2024)

Fact 1: The definition of robotics is older than robots themselves

In the case of robotics, the definition preceded its actual origin. What first started as a utopian literary idea of machines performing specific tasks that were originally carried out by humans has since become reality. Robots are widely used to replace human labor when it comes to repetitive and strenuous tasks in industries such as building, automobile and industrial manufacturing, or healthcare.1

While they’re meant to exceed humans in strength and efficiency, human traits are used as models for robot construction. Depending on the type of robot and their application, they are designed to mimic a sense of vision, touch, or the ability to sense differences in temperature.

Further, robot control systems are also determined by the tasks the robot is meant to perform in the future. There are robots that are controlled remotely and robotic systems that are equipped with artificial intelligence. The latter were programmed to perform tasks independently without an additional control source.

Fact 2: The history of robotics roots in fiction

The history of robotics is multifaceted, as this field developed on different levels. While the idea of intelligent machines dates back as far as Homer’s Iliad (800 B.C.), the first mention of the word “robot” can be found in Karel Čapek’s play Rossum’s Universal Robots (1920), meaning machines that are able to work twice as much as human beings.2

Čapek derived the term robot from “robota”, which translates to “to work” in Polish. However, the science fiction author who is most acknowledged for the use of the term is the American writer Isaac Asimov, author of The Robot Series (1940-1995), a collection of 37 short-stories.

Fact 3: There are five fields of robotics

Robots have several qualities. In the following, we will introduce five fields of robotics that are responsible for their success:

1. Operations in hazardous environments

Robots can be used to replace human labor in environments that are hazardous to humans. With an operator interface that functions as a bridge between robot and human, communication with the robot can be established. To achieve successful communication between workers and robots, it is important that the controlling device follows a hands-on approach and is easy to use.

2. Transport and locomotion

Another main asset of robotics is the transport of certain items or movement through specific areas. Depending on the type of robot and its use, mobile robots are often designed to mimic human motions, like in the form of robotic arms. Other models that need to be interactive with their environment, such as robot prototypes used for space missions, rely on wheels and other forms of movement and locomotion.

3. Interaction with the environment

As robots need to be able to interact with their environment in order to perform specific tasks, they rely on the installment of effectors and manipulators. These can come in different forms, like humanoid hands to pick things up and move them, whereas industrial automation systems often rely on pinch mechanisms to move heavy objects from one place to the other.

4. Precise execution of commands

It might seem obvious, but every robot needs to be able to execute the commands it is given. Therefore, programming is one of the most important aspects of robotics and an area that is evolving rapidly within the field of computer science. While traditional programming methods are applied in advance and don’t change on their own, there are different types of robots that use deep learning through algorithms to approach their tasks. However, this does not mean that human commands are obsolete, as even smart robots rely on programming and are often not capable of autonomous decision-making (although robotics research is engaged in optimizing decision-making processes performed by robots).

5. Gathering of information

In order to gather information about the environment the robot operates in, it needs sensory and perception features. Depending on the designated use of robots, they need to be equipped with sensors like computer vision or temperature perception.

Source: Robotics and Automation News3

Fact 4: 9 types of robotics can be distinguished

While some categories may overlap or be hard to differentiate, there are nine main types of robotics that are commonly referred to:

- Industrial robots

- Collaborative robots (cobots)

- Mobile robots

- Autonomous mobile robots (AMRs)

- Service robots

- Nanorobots

- Humanoid robots

- Educational robots

- Medical robots

Manufacturers of robotic solutions often specialize in one or some specific types of robots, and are to be found all over the world – from companies in Europe like ESSERT Robotics in Germany or the English company CKF to ATI Industrial Automation in America, Pudu Technologies in China, or FANUC in Japan.

What is an industrial robot?

As its name already suggests, an industrial robot is used for industrial manufacturing. Mostly, this means taking over strenuous and dangerous tasks that originally had to be performed by workers.

Industrial robots have the potential to speed up certain aspects of the supply chain, preventing bottlenecks and saving production costs. There are several important criteria when selecting industrial robots for manufacturing, including payload capacity and reach.4

While industrial robots have widely been in use in large-scale industrial manufacturing, the market is becoming more accessible to middle and smaller productions as well. These automation solutions have to be adjustable and flexible to cater to the needs of high mix / low volume customized productions.

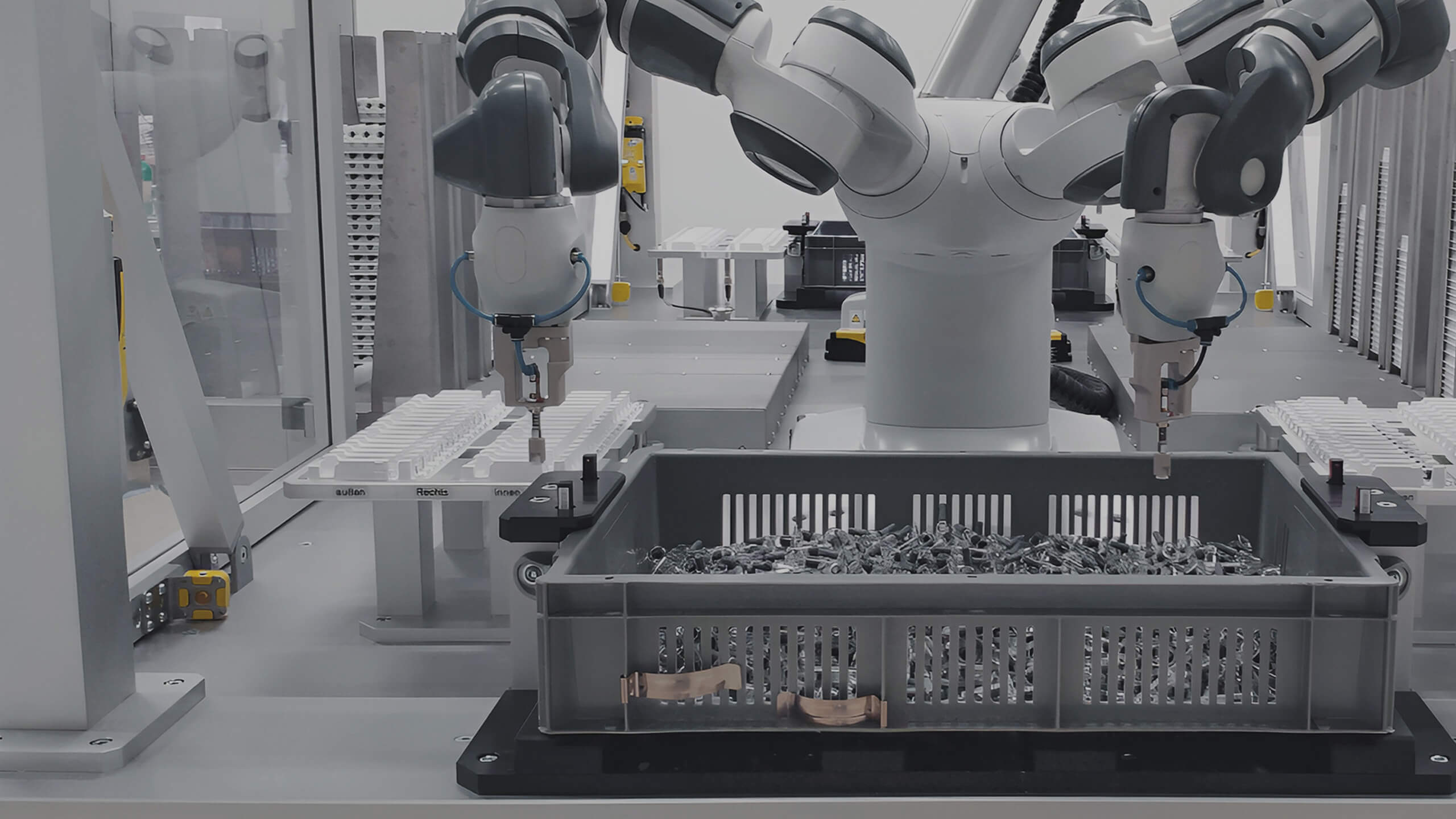

ESSERT Robotics’ vision is to support customized healthcare productions with automated solutions that enable them to switch quickly between development and production phases. With flexible and agile automation modules that can easily be combined and rearranged, small-scale production can become more streamlined and profit from less down-time during production steps. Furthermore, the solutions of ESSERT Robotics can integrate robotic systems by leading suppliers, thanks to the standardized nature or the company’s platform.

Cobot – more than a robot

The term cobot or collaborative robot is relatively new and describes a robot that is working alongside humans and supports them in their tasks without the need for a safety barrier. They are designed to share the same workspace, often considerably smaller than industrial robots and easy to use. The main difference between cobots and industrial robots is that industrial robots are autonomous machines that often function with a minimal level of human interaction.5

Cobots can perform numerous tasks depending on their design. To allow manufacturers to maintain flexibility during small-scale productions, solutions by ESSERT Robotics can be combined with equipment for different production steps and also allow collaboration with humans.

Fact 5: The applications of robots are constantly increasing

As the demand for automated solutions increases due to worker shortages and rising competitiveness throughout different industries, robotics applications are expanding simultaneously. Global market value for 2024 is predicted to reach USD 38.24 billion, with a main share of automation solutions used as service robots.6

The application of robot technology has proven to be beneficial in regard to efficiency, consistency and profitability. Robots are used in different industries, like space travel, building, food, electronics, the automotive and the pharmaceutical industry, to name just a few.7

Robots in manufacturing

The future of robotics in manufacturing is constantly evolving. Robots may not only be used for assembly, packaging, dispensing or the transportation of material; due to sensory traits and actuators, it became possible to use them for quality control as well. With the help of control systems that inform workers in real-time about malfunctions, production becomes more reliable, too.

Robotic automation in the pharmaceutical industry

There are many applications for robotics in the pharma industry. Robots are able to perform medical functions like rehabilitation and physiotherapy, and can even be used in the form of exoskeletons or as artificial limbs.

In the production of pharmaceuticals, where consistency and quality control are essential, robots are used for quality checks, temperature surveillance, documentation, medical device assembly or aseptic dispensing and filling mechanisms, such as pipetting.8

Fact 6: Robots in pharma are no longer limited to LMHV production

Even though the use of automation has long been limited to low mix / high volume productions, new flexible and adaptable automation solutions now find their way in high mix / low volume applications as well.

In small-scale productions like clinical studies for research institutes or the production of customized medicine, manufacturers can profit from robotics solutions that are adaptable and flexible to react to the market’s changing demand.

As demographics are changing and workers enter the work field later in life, robotics are required to fill a gap in smaller-scale pharmaceutical productions. With their help, workers can be freed of strenuous tasks and dedicate their time to more important work.

Fact 7: Modularity and flexibility in robotics are key

The requirements in the pharmaceutical industry can change rapidly, which constantly poses new challenges for manufacturers. Producers have to be able to react to customer demands and up-scale or down-scale when it is needed.

Modularity and flexibility of robotics are especially important when it comes to new trends in the industry, like the production of personalized medicine. This field is highly customer oriented and mostly based on small batches. Therefore, manufacturers have to be able to easily switch between development and manufacturing mode. This calls for automated solutions that can be adapted to each step of the production when it is needed.

ESSERT Robotics – advanced robotic solutions for exacting standards

The use cases for robotics are seemingly endless. When it comes to the pharmaceutical industry, the benefits of automation are undeniable. Still, new flexible and adaptable advancements are called for to make automated production more efficient in high mix / low volume environments.

ESSERT Robotics’ ADVANCED Robotic Workstation was developed to address the challenges that manufacturers have to face when producing low quantities of personalized medicine. These challenges include short adaption times and frequent switches between development and production phases.

Therefore, the ADVANCED Robotic Workstation is compatible with robots from several major brands in the robotics industry, such as FANUC, ABB, or Stäubli. This is possible thanks to its standardized platform, based on which an individual set-up can be tailored to the customer’s automation goals.

The interoperability of the ADVANCED Robotic Workstation allows it to be easily adapted to different production steps, reducing downtime in the production process. The individually designed workstation modules consist of stainless steel components and are GMP-compliant.

With the ESSERT MicroFactory, there is the option to automate complete production chains by combining different workstations together. This does not only increase efficiency, but it makes pharmaceutical production processes safer, as it reduces the need for manual intervention. The platform is suitable for both start-ups and established pharmaceutical companies, allowing to master scale-up challenges through agile modularity.

Read more about robotics

Robots in manufacturing: revolutionizing production processes

Robotic manufacturing companies

Cobot – all you need to know about collaborative robots

What is an industrial robot?

Robotics in the pharmaceutical industry

- Ben-Ari, M., Mondada, F. (2018). Robots and Their Applications . In: Elements of Robotics. Springer, Cham. https://doi.org/10.1007/978-3-319-62533-1_1 ↩︎

- Liveley, Genevieve, and Sam Thomas, ‘Homer’s Intelligent Machines: AI in Antiquity’, in Stephen Cave, Kanta Dihal, and Sarah Dillon (eds), AI Narratives: A History of Imaginative Thinking about Intelligent Machines (Oxford, 2020; online edn, Oxford Academic, 23 Apr. 2020), https://doi.org/10.1093/oso/9780198846666.003.0002, accessed 11 Feb. 2024. ↩︎

- https://roboticsandautomationnews.com/2022/12/28/the-major-fields-of-robotics-in-2023/58882/ ↩︎

- Robotics for Electronics Manufacturing Principles and Applications in Cleanroom Automation , pp. 1 – 11. Cambridge University Press, 2010. DOI: https://doi.org/10.1017/CBO9780511712173.002 ↩︎

- Shirine El Zaatari, Mohamed Marei, Weidong Li, Zahid Usman. Cobot programming for collaborative industrial tasks: An overview, Robotics and Autonomous Systems. Volume 116, 2019. https://doi.org/10.1016/j.robot.2019.03.003. ↩︎

- https://www.statista.com/outlook/tmo/robotics/worldwide ↩︎

- M. Edwards. Robots in industry: “An overview”. Applied Ergonomics. Volume 15, Issue 1,1984, Pages 45-53. DOI: https://doi.org/10.1016/S0003-6870(84)90121-2. ↩︎

- Bhatnagar, N. (2020). Role of Robotic Process Automation in Pharmaceutical Industries. In: Hassanien, A., Azar, A., Gaber, T., Bhatnagar, R., F. Tolba, M. (eds) The International Conference on Advanced Machine Learning Technologies and Applications (AMLTA2019). AMLTA 2019. Advances in Intelligent Systems and Computing, vol 921. Springer, Cham. https://doi.org/10.1007/978-3-030-14118-9_50 ↩︎