HUMMEL AG reduces its manufacturing costs

Summary

HUMMEL AG is a renowned manufacturer of connection technology and components for the electrical engineering and heating sectors. For more than 70 years, the medium-sized family-owned company has stood for quality, precision, reliability and a strong sense of service. Their wide product range serves well-known customers from the heating & sanitary industry, food industry, energy sector, transport logistics and many more.

In order to make internal production processes more effective and significantly reduce manufacturing times, HUMMEL AG was looking for a flexible automation solution that could handle not only high product variance but also future requirements.

The focus was not only on economic factors such as reducing production costs and increasing availability and quality. Likewise, the automation had to be easy to operate for existing skilled workers and create the possibility to relieve employees from performing monotonous manual tasks, such as the assembly of different O-ring types.

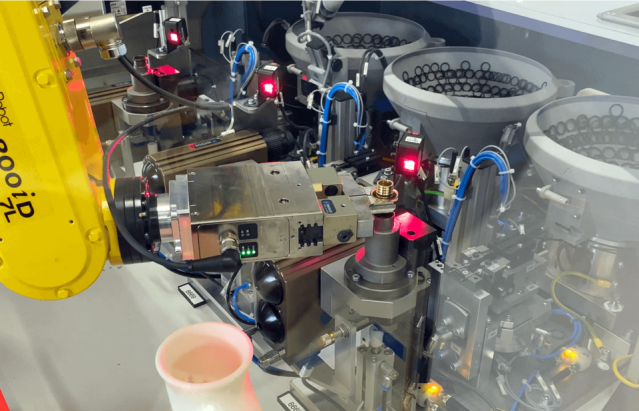

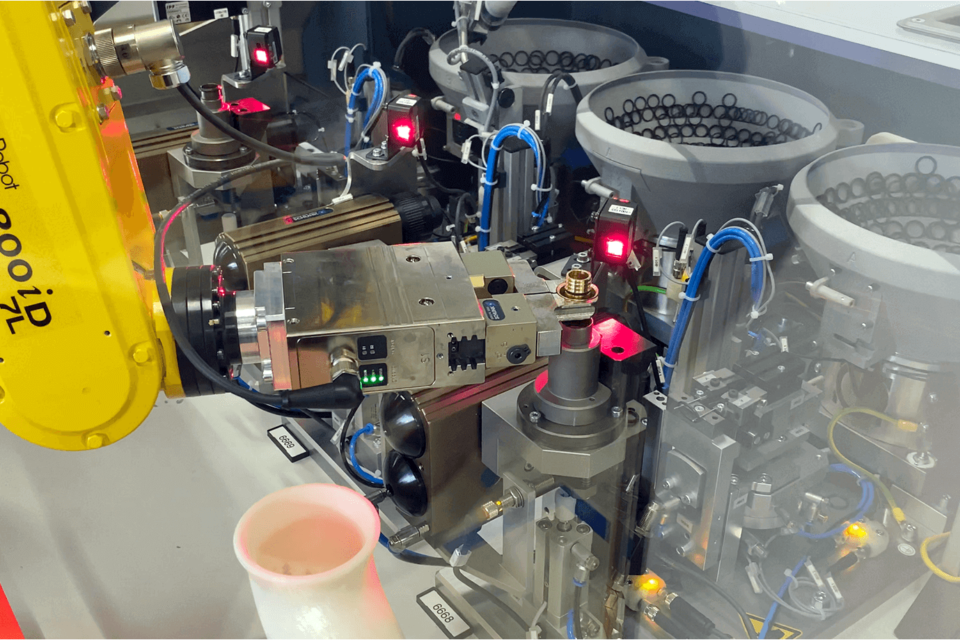

The robot workstation used with intelligent camera technology detects bulk material provided and feeds it to the integrated O-ring assembly stations. Precise positioning of the components and permanent real-time monitoring guarantee very high process and product quality.

The challenge

The monotonous task of assembling various O-rings, which had previously been carried out by employees, was to be automated. One of the goals was not only to entrust employees with more attractive tasks, but also to increase the quality of production through intelligent automation processes in order to ultimately reduce costs. The focus was always on the contradiction between performance and a wide range of variants.

“The challenge at HUMMEL AG lies in the combination of large batch sizes and high product variance at the same time, which demands maximum flexibility from the automation solution.

In addition, the user interface must be as simple and intuitive as possible to avoid time-consuming and costly programming work.”

“Market requirements and products change very quickly these days. We have to be able to react immediately to changes, even if requirements change as a result. Especially with many different components, the use of robots proves to be an extremely flexible solution,” explains Martin Rasch.

The current status

The automation solution impresses with a high degree of flexibility and the implementation of a wide range of variants for varying quantities.

“ESSERT’s standardized robot platform guarantees rapid availability and makes it more cost-effective than classic special solutions. The modularity also enables subsequent cascadability. Another system has already been ordered,” says Martin Rasch.

With the automation solution, HUMMEL AG is able to sustainably reduce its manufacturing costs and further increase process and product quality.