VETTER Pharma automates its material separation process

Summary

Vetter is a leading global Contract Development and Manufacturing Organization

(CDMO) with headquarters in Ravensburg, Germany, and production facilities in

Germany and the USA. With many years of experience and the dedication of its

approximately 5,000 employees worldwide, the company provides support from early

process development through clinical and commercial filling to a wide range of

packaging solutions for vials, syringes and cartridges. Vetter’s customers represent the

full range from small to large companies in the pharmaceutical and biotechnology

industries. With its many years of experience in the filling of sensitive active ingredients,

the pharmaceutical service provider has made it its business to develop injection

systems together with its clients for the continuous improvement of patient safety,

comfort and compliance.

In order to make internal automation more flexible, among other things to meet the trend

towards smaller batches in the pharmaceutical industry, the company was looking for an

innovative, flexible and above all reproducible automation solution. The goal is to

automate previously manual processes, such as the separation of transparent glass

bodies (syringes) by “reaching into the box” and depositing them in trays provided for

this purpose.

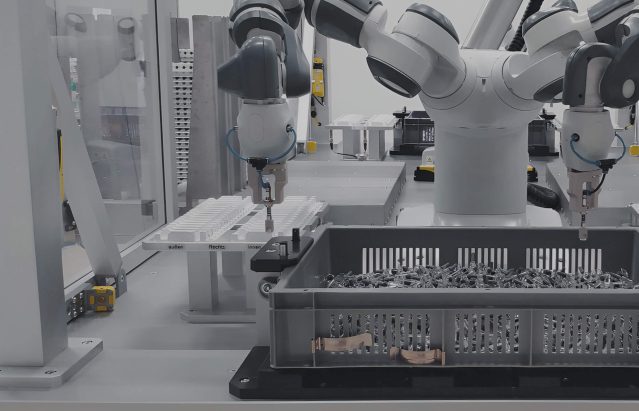

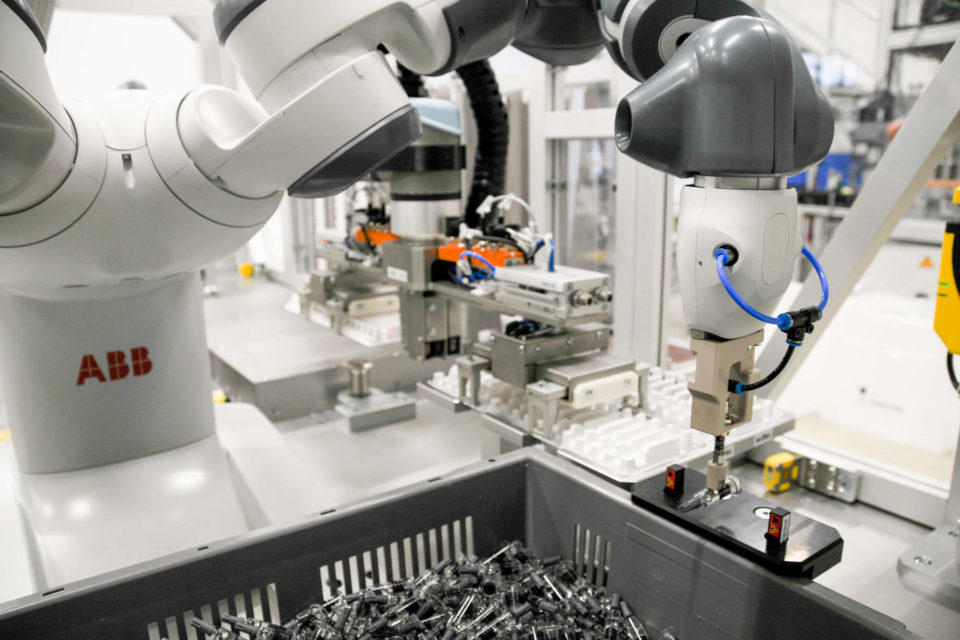

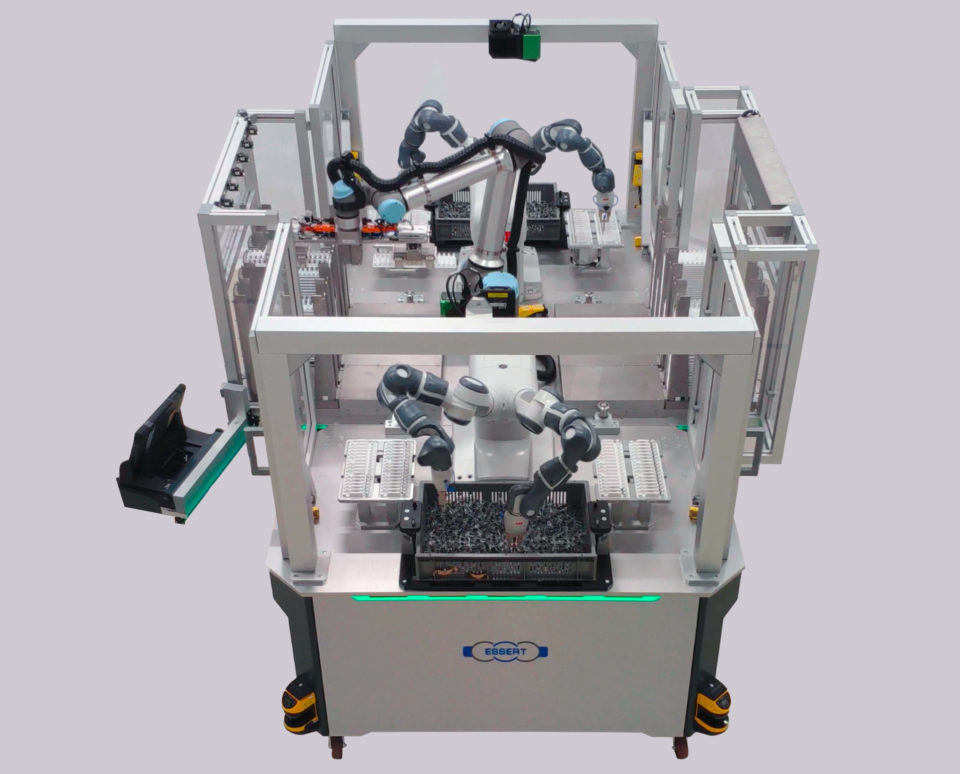

Three integrated robotic workstations take over the material separation, as well as the

provision of empty trays and the restacking of full trays, with the aid of the latest 3D

vision technology and ESSERT’s speed bin picking process.

The use of the flexible bin-picking system not only has a positive effect on process

quality, but also significantly reduces human intervention and thus the risk of possible

product contamination. This enables employees to perform more efficient and complex

tasks.

The Bin Picking solution meets all necessary criteria for 100% compliant operation in the pharmaceutical industry. Another robotic solution in the field of syringe assembly (assembly of plunger rods and backstops) is currently being finalized together with ESSERT.

The Challenge

Monotonous, manual tasks, such as separating transparent glass jars and supplying

empty trays and stacking full trays back, were to be automated. One of the goals was

not only to entrust qualified employees with more demanding tasks, but also to

positively influence process and product quality. In order to familiarize the entire

workforce with this topic at an early stage, a preliminary robot cell was presented in

advance at the company’s works meeting.

„One of the big challenges for us was reproducibility and cooperative/collaborative

collaboration between man and machine. Performance is an equally important factor,“ explains Markus Behrendt, project manager responsible for the plant and site expansion at Vetter.

We have been familiar with classic robot cells in our everyday production since the

early 1990s. The declared goal is to include innovative, open and powerful systems in

our production. To advance this goal, we considered purchasing components or working with integrators during the evaluation phase,” Behrendt continued.“We talked to many people in the industry and to various robot manufacturers, for

example at the Hannover Messe. In the process, the name ESSERT came up again and again.”

The current status

The robot platform convinces with its flexibility, reproducibility, the integration of

state-of-the-art vision technologies as well as with the speed bin picking process.

“ESSERT has succeeded in developing a platform that can be used in the highest

degree of flexibility and modularity, regardless of the industry,” says Arno Schroff,

department manager for plant and site development at Vetter.“The functional design with the built-in mode illumination is well thought-out and of high

quality. The advantages of the platform are clear: Whether something has to be gripped,

assembled or inspected, the robotic platform offers numerous fields of application.

Another system has therefore already been ordered.”

With the automation solution, Vetter is able to further advance its strategic goals, make

the jobs of its employees more attractive, and positively influence process and product

quality.