How are Robots Used in Pharmaceutical Manufacturing?

Robots are used in pharmaceutical manufacturing for tasks such as drug formulation, bin picking, packaging, medical device assembly or in inspection and testing processes.

As pharmaceutical manufacturing demands highest precision, efficiency, and adherence to strict quality standards, robots emerge as helpful collaborators. The synergy between human expertise and robotic capabilities ensures increased productivity and quality, for an advancement in innovative medical solutions.

This blog post navigates the landscape of robotic applications, from drug formulation to the assembly of critical medical devices such as syringes, PENs, and autoinjectors.

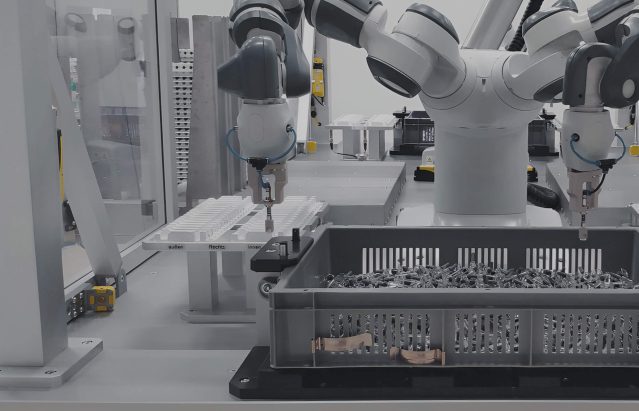

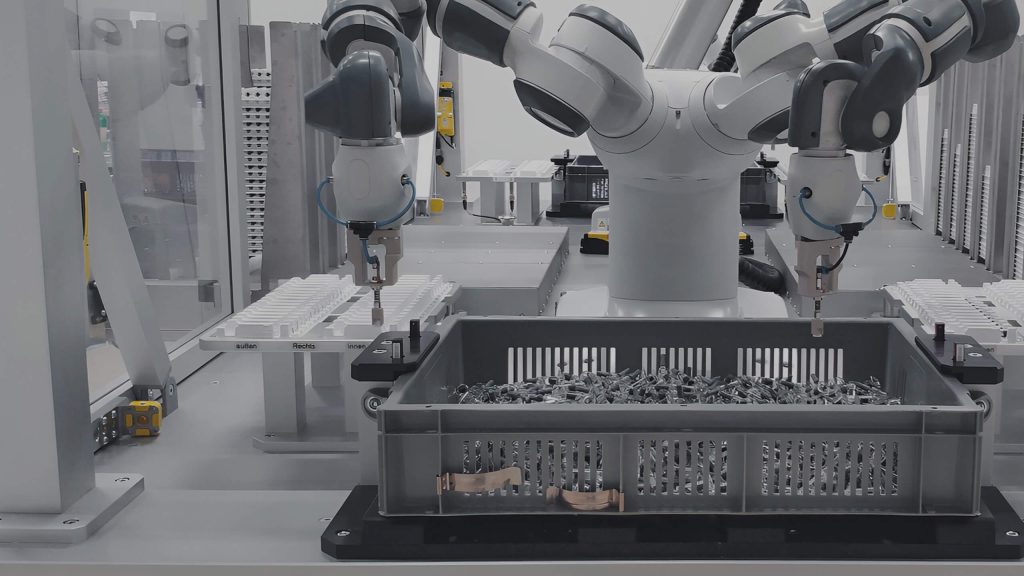

Robotic Bin Picking and Pick-and-Place Tasks

Robots play a key role in handling individual, loose components within the pharmaceutical manufacturing environment. These tasks involve automatically separating transparent injection bulk materials, such as syringe barrels, from trays or bins.

The tasks and advantages of bin picking and placing applications include:

- Efficiency in picking and handling various materials

- Precision and accurate placement of materials

- Speed and consistency leading to increased throughput

At ESSERT Robotics we developed an award-winning solution. Together with our customer Vetter Pharma, we developed the “Speed Bin Picking” solution based on our Advanced Robotic Workstation and won the ISPE RAYA Award in the category “Fill & Finish”.

Utilizing advanced camera and tactile sensor technology, the bin picking solution ensures precision and efficiency. Even sensitive and transparent medical products such as syringes or vials are precisely detected and safely handled. This innovative approach not only minimizes the risk of breakage but also enhances safety for staff, reduces product loss, and provides a modular, future-ready solution for evolving workflows in pharmaceutical manufacturing.

Medical Device Assembly with Robotics

The assembly of medical devices, including syringes, PENs, and autoinjectors benefits from the integration of robotic systems. The use of robotics contributes to maintaining sterile manufacturing environments. This is especially critical for medical devices that come into direct contact with patients.

Automated robotic solutions reduce the time required for assembling medical devices. This efficiency is vital in meeting demand and maintaining a continuous supply of essential medical products. Furthermore, flexible and adaptable robotic systems allow for the customization of medical devices without extensive retooling. This flexibility is essential in an industry where products often require tailored configurations to meet specific medical requirements.

Emphasizing flexibility and modularity, ESSERT Robotics offers a future-proof medical device assembly solution that caters to the demands of High Mix / Low Volume (HMLV) manufacturing, particularly for syringes, PENs, and auto-injectors. Our modular, flexible, and scalable assembly line, the ESSERT MicroFactory, addresses the challenges of variable batch sizes and high format variance, ensuring efficient and precise production.

Robotic Applications in Laboratories

Lab automation through robotics offers unparalleled consistency and precision. Automated systems adeptly handle tasks such as mixing, dispensing, and measuring of lab reagents and samples, thereby enhancing the quality of experimental results while optimizing workflow efficiency.

How are robots utilized in lab automation? Here are two examples:

- Precise Measurement: Robots demonstrate highest accuracy in autonomously measuring and dispensing a wide range of lab components, ensuring the precise formulation of experimental samples and solutions.

- Uniform Mixing: Through automated procedures, robots ensure the uniform blending of lab reagents and samples, minimizing variability and enhancing the reproducibility of experimental outcomes.

Quality Control in Pharmaceutical Manufacturing

Another application of robots in pharmaceutical manufacturing is in automated quality control, from inspecting product integrity to verifying adherence to regulatory standards.

Automated inspection processes in pharmaceutical manufacturing utilize robotics with sophisticated sensors and vision systems. Robotic systems excel in detecting even minute defects, maintaining manufacturing integrity, and delivering safe products. They contribute to data accuracy and traceability, supporting real-time monitoring and compliance with industry regulations.

Our expertise in this area lies particularly in medical device testing solutions. ESSERT Robotics provides an innovative solution to automate the programming and testing of medical devices, ensuring a streamlined and reproducible workflow. Medical device testing involves a range of assays, from biological compatibility to performance testing, conducted to guarantee safe and effective use in patients, aligning with strict international standards set by regulatory authorities like FDA (Food and drug administration) or MDR (Medical device regulation europe).

Robotic Packaging and Labeling

The final stage in the manufacturing process involves packaging medical devices and other products that demand specialized protection during transportation and storage. Packaging and labeling of products are critical components that directly impact the supply chain. Robots have become indispensable in automating these processes, optimizing the way pharmaceutical products are prepared for distribution and consumption.

Automated Packaging Processes

Automated packaging of medical products involves the use of robotic systems to efficiently and precisely package pharmaceuticals or medical devices for distribution and consumption. Robots pick and place items into containers or blister packs and bring together several components for a safe secondary packaging. It is a crucial task to protect valuable goods from environmental influences during transport and storage.

Efficient Labeling Systems

Autonomous labeling refers to the process of applying labels to pharmaceutical products without direct human intervention. Robots handle the application of labels with precision, reducing the likelihood of mistakes associated with manual labeling.

It is essential that robotic solutions can accommodate the diverse range of pharmaceutical products. However, not every industrial robot provides this level of adaptability. ESSERT Robotics recognizes and addresses this crucial requirement with the solution for packaging medical products.

This innovative robotic solution ensures the necessary flexibility to handle different pharmaceutical product specifications, without the need for time-consuming and complicated reconfiguration. The transition is achieved through a simple software-based process at the press of a button, ensuring a rapid and efficient changeover.

Conclusion: Applications of robotics in pharmaceutical manufacturing

In summary, the integration of robotics in pharmaceutical manufacturing has significantly enhanced precision, efficiency, and adaptability across various pharmaceutical processes.

At ESSERT Robotics, we offer a singular standardized solution—the Advanced Robotic Workstation. Our robotic workstation’s adaptability to diverse automation needs positions us as innovators, consistently exploring new applications, especially within the realm of smaller batch sizes.

Combining these workstations modules into an ESSERT MicroFactory creates a flexible production line suitable for manufacturing and assembly tasks for various pharmaceutical products. The unique architecture of the MicroFactory is characterized by its modular and scalable build-up, allowing each module to be swiftly changed. This capability facilitates the production of different products with short changeovers within a few minutes. Additionally, pre-validation of new modules is possible without any effect on the existing manufacturing line.